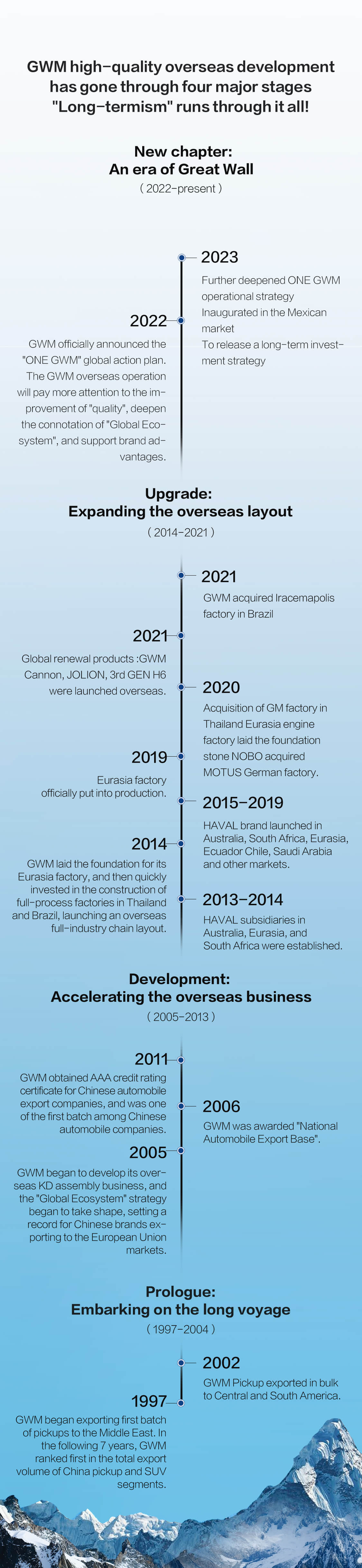

Great Wall Motor is one of the first Chinese automobile enterprises to go abroad. It has

been exporting since 1998.

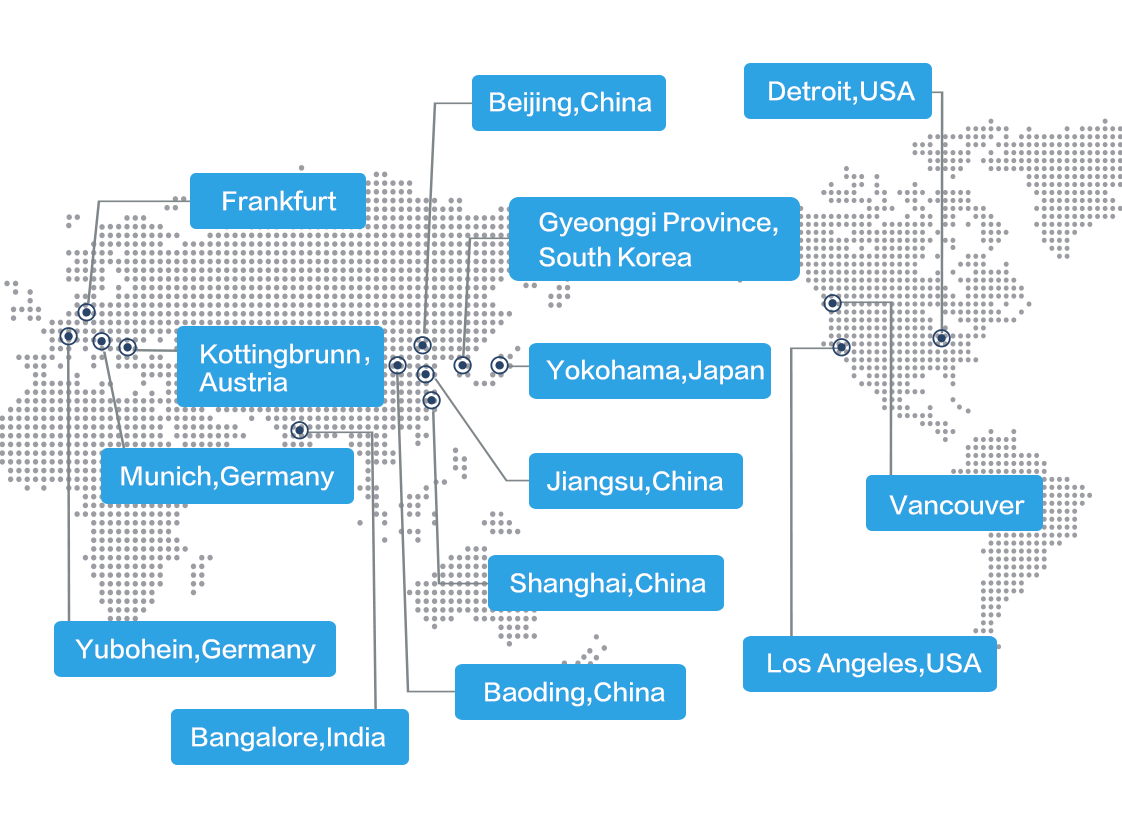

At present, Great Wall Motor sales network covers the world, exporting to more than 170

countries and regions, and its overseas sales regions cover Eurasia, Thailand, Brazil,

Australia, Saudi Arabia, South Africa, Chile, Ecuador, as well as the core city business

circles of many countries and regions in the European region, with more than 700, and the

cumulative overseas sales of more than 1 million vehicles.

Great Wall Motor has established overseas parts center libraries in key markets such as

Australia, South Africa and the Middle East to meet the needs of the after-sales market and

improve customer satisfaction.

Great Wall Motor opened a subsidiary in Munich, Germany, and set up a European headquarters.

It also has a regional marketing center in Eurasia, Australia, South Africa, Saudi Arabia,

Chile and other key construction areas.