FTXT Makes Breakthrough in Core Technologies for Three Major Hydrogen Energy Products GWM's Strategic Layout of Hydrogen Energy Development Will be Further Advanced

On September 13, an "Ultimate Technology•Reliable Power" super conference was held online. FTXT Energy Technology Co., Ltd. (hereinafter referred to as FTXT), a subsidiary of GWM, released its core products including 95 kW passenger-car fuel cell system engines, platform-based fuel cell stacks that can be expanded up to 150 kW, and 70 MPa high-pressure hydrogen storage cylinder valves and pressure reducing valves.

Summary:

FTXT releases its core products including 95 kW passenger-car fuel cell system engines, platform-based fuel cell stacks that can be expanded up to 150 kW, and 70 MPa high-pressure hydrogen storage cylinder valves and pressure reducing valves.

The research and development of FTXT's three major products have lasted for 5 years, with an R&D investment of RMB 1.57 billion. A total of 363 key technology patents have been applied and granted.

GWM's first fuel cell SUV will be mass-produced in 2021.

On September 13, an "Ultimate Technology•Reliable Power" super conference was held online. FTXT Energy Technology Co., Ltd. (hereinafter referred to as FTXT), a subsidiary of GWM, released its core products including 95 kW passenger-car fuel cell system engines, platform-based fuel cell stacks that can be expanded up to 150 kW, and 70 MPa high-pressure hydrogen storage cylinder valves and pressure reducing valves. This conference officially announced FTXT's launch of a "joint fleet" for hydrogen energy development, and GWM's strategic layout of hydrogen energy development will be further advanced.

"Extreme Technology•Reliable Power" Super Conference

363 Patents 1,045 Rigorous Tests FTXT Makes Breakthroughs in Key Core Hydrogen Energy Technologies

Since the beginning of 2016, GWM has listed the development of hydrogen fuel cells as a key project, aiming at the world's cutting-edge key technological fields of hydrogen fuel cells, and carrying out platform-based component design for passenger car and commercial vehicle markets. So far, it has invested RMB 1.57 billion of its own capital in product development in total. FTXT, a subsidiary of GWM, focuses on the R&D, manufacturing, and sales of hydrogen energy technology. It has a professional R&D team, as well as hydrogen energy test bases, fuel cell trial production centers, hydrogen production and liquefaction plants, supporting vehicle test sites, climatic chambers, and other high-quality resources.

After five years of exploration, FTXT has successfully applied for 363 patents of key core technologies in the field of hydrogen energy and fuel cell. In the R&D process, in addition to being in strict compliance with the product development V process, all products have gone through 1,045 rigorous tests, ensuring super reliability from the source of design and development. Zhang Jinhua, Secretary-general of the China Society of Automotive Engineers, stated at the conference that FTXT has invested heavily in the development of hydrogen energy and fuel cell vehicle business and mastered key core technologies, which reflects GWM's dedication and professionalism, and hoped that FTXT would become a model of national brands in the industry, make persistent efforts, and lead the technological innovation in the industry. Wu Zhixin, Deputy General Manager of China Automotive Technology and Research Center Co., Ltd., praised: "FTXT has presented the wisdom of its own brand by offering solutions to problems and has provided an excellent case for enterprises in the industry."

Core Technical Parameters of 95 kW Passenger-car Fuel Cell System Engine

The 95 kW fuel cell engine launched by FTXT has gone through component testing, module testing, system testing, powertrain testing, and vehicle testing successively, including thousands of rigorous tests on 5 levels. It is equipped with a "proportional solenoid valve + single ejector" hydrogen circulation module, which can reduce the cost by 100% compared with the hydrogen circulation module using a hydrogen circulation pump.

Fuel Cell Engine Test System

Platform-based Fuel Cell Stack That Can Be Expanded Up to 150 kW

The 150 kW platform-based fuel cell stack has achieved comprehensive breakthroughs in the high power of fuel cell stack and the voltage uniformity of single cells of the stack. With the help of the five "trump cards" of bipolar plate design, membrane electrode development, overall uniformity simulation of the stack, stacking process control, and single-cell drainage performance, as well as the "NODS system" developed by FTXT, remote online diagnosis and upgrade of the system, real-time monitoring of the working state of the fuel cell, and remote fault diagnosis and cloud upgrading are realized. With continuous adjustment of the corresponding control strategies, the service life of the fuel cell stack is effectively extended by more than 20%.

70 MPa High-pressure Cylinder Valve

The 70 MPa high-pressure hydrogen storage cylinder valve and the two-stage pressure reducing valve have been subjected to the mainstream design of high integration, light weight, and low power consumption for high-pressure hydrogen storage valves. The complete hydrogen storage coordination is achieved only by the process layout of hydrogen refueling receptacle-cylinder valve-hydrogen cylinder-pressure reducing valve bank-fuel cell system, which reduces the hazard of leakage from the root. The total number of cylinder valve parts is reduced by more than 20% compared with the current mainstream products in the market. The pressure reducing valve bank is integrated with a one-way valve, a bipolar filter unit, and a high-pressure diverter unit. The total weight of the two valves is equivalent to 1/3 of that of the current mainstream products in the market. In terms of safety and tightness, the leakage rate is far less than the limits specified in domestic and foreign standards according to the hydrogen leakage test.

GWM's First Fuel Cell SUV Will Be Mass-produced in 2021

Among the three core fuel cell components released by FTXT, the 95 kW passenger-car fuel cell system engine has been successfully applied to the first fuel cell SUV that will be launched by GWM soon, and will be mass-produced in 2021.

At the same time, based on its position as an expert in hydrogen energy for vehicles, FTXT adopts the "passenger car and commercial vehicle" two-legged strategy. Shanghai Fuel Cell Vehicle Powertrain Co., Ltd., a subsidiary of FTXT, is positioned as an important strategic support for the R&D of domestic commercial vehicle fuel cell systems. The fuel cell heavy-duty truck model launched together with Dayun Automobile Co., Ltd., is equipped with an independently developed 100 kW commercial fuel cell engine - "Chaoyue 300E", breaking through the service life limit of 10,000 hours and having a one-time vehicle endurance mileage of 1,100 km.

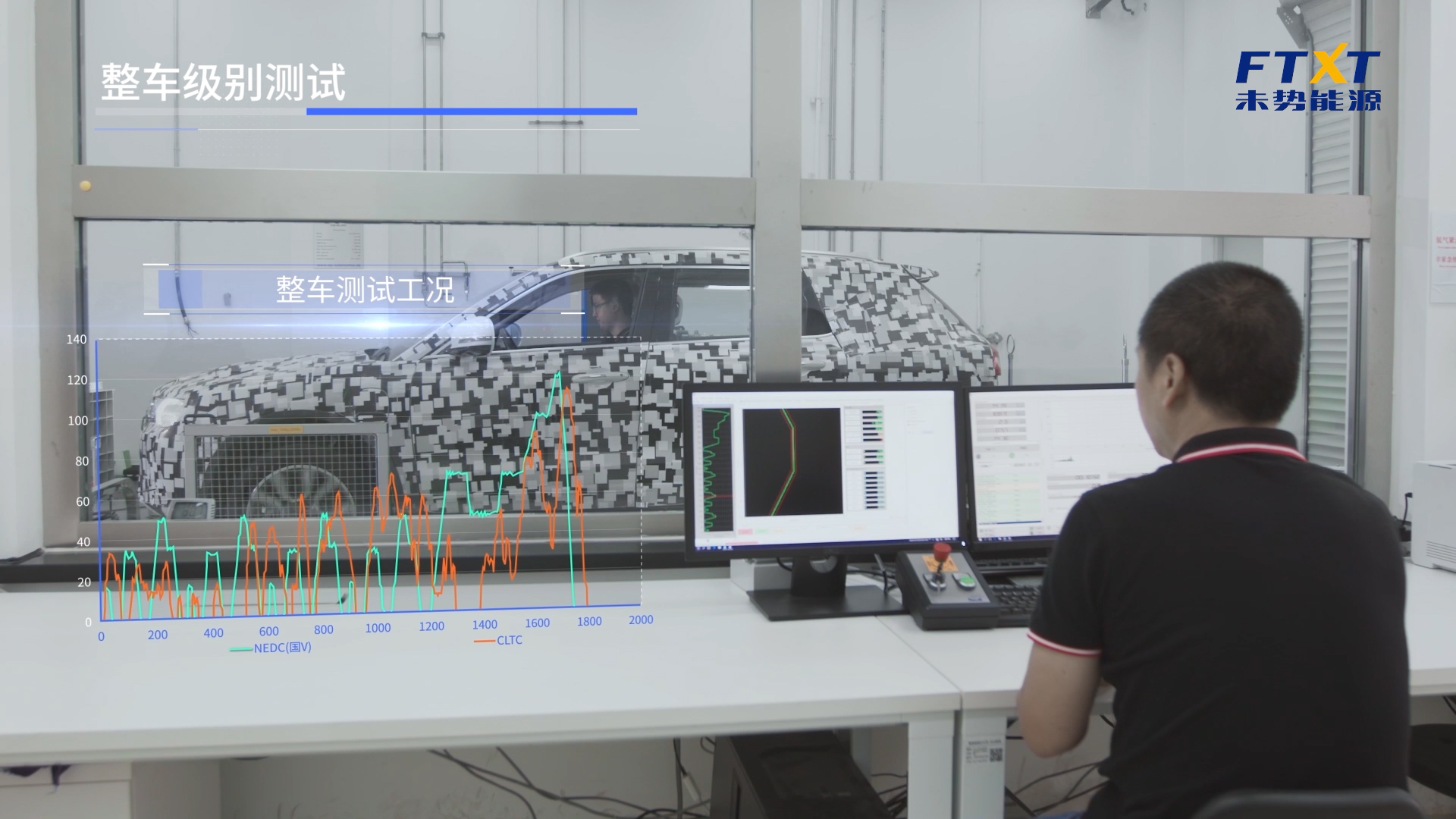

Test under Vehicle-level Conditions

Both the 70 MPa hydrogen storage cylinder valve and the pressure reducing valve can be mass-produced now, and the 70 MPa IV hydrogen storage cylinder will be officially launched in 2021.

FTXT's 1,000-unit Independent High-power Stack Production Line

The 150 kW high-power independent stack production line with a designed annual capacity of 1,000 units was put into use in July this year, and the product will be officially put on the market in 2021.

FTXT has launched its "joint fleet" of key core components in the fields of hydrogen energy and fuel cell to solve the technological "bottlenecks" in the industry, improve product reliability, and reduce product costs. It also indicates that GWM's strategic layout in the fields of hydrogen energy and fuel cell has begun to advance in depth.