L.E.M.O.N. Platform’s upgraded “Weight Loss”: Adoption of 2000MPa Thermo-forming Steel

As a common knowledge, light weight is of great significance to the machinery industry, particularly to the automobile industry, and launching of the Great Wall Motors (GWM) L.E.M.O.N. Platform further evidenced this knowledge.

As a common knowledge, light weight is of great significance to the machinery industry, particularly to the automobile industry, and launching of the Great Wall Motors (GWM) L.E.M.O.N. Platform further evidenced this knowledge.

In September, 2020, both the third-generation HAVAL H6 and the HAVALDagou, which are developed on the basis of the L.E.M.O.N. Platform, made their debuts. Of which, the third-generation HAVAL H6, reputed as “Champion Car”, continued its strong performance, with sales volume rocketing to 11,516 units. In addition, HAVALDagou, which was launched onto the market on the eve of Auto China 2020, also achieved remarkable performance, and its sales volume hit 3,045 units within only five days, marking an outstanding result made in the first month of marketing.

HAVAL Dagou

Accordingly, L.E.M.O.N. Platform received high recognition from insiders, and strong performance of the third-generation HAVAL H6 and the HAVAL Dagou mirrors consumers’ support and recognition to the car models developed on the L.E.M.O.N. Platform.

What will the light weight, a gold business card of L.E.M.O.N. Platform, bring to consumers?

Some consumers probably know little about the light weight’s significance to the carmakers. We will brief you on the users’ better experience from improvement of light weight.

First, in terms of cleaning, energy conservation and emission reduction is a direct driving force to light weight. With implementation of the National VI Emission Standard, all carmakers have focused their eyes on improvement of the vehicle emission efficiency.

Second, in the new energy sector, lower dead weight means better driving range, which is very significant in development and popularization of new-energy vehicles.

Joint stand of GWM at Auto China 2020

Third, from the perspective of vehicle maneuverability, light weight leads to improvement of accelerating performance, braking performance, steering performance, and gradeability, enabling consumers to feel more delightful driving experience.

Surely, the light weight is premised on driving safety and comfort: better lightweight performance must be based on no compromise to safety and comfort and improvement of fuel economy and dynamic, which is the true meaning of light weight. That is right the ultimate goal of the L.E.M.O.N. Platform.

L.E.M.O.N. Platform’s three improvements in light weight: fuel economy rises by 14.5%

To achieve the L.E.M.O.N. Platform’s ultimate lightweight performance, the GWM makes three improvements to fundamentally achieve the light weight and reach the industry top level.

First, structural improvement: adjust the material arrangement path, and fully improve the torsion resistance and roof crush strength.

Improvement of the body structure is the key to light weight. At the inception phase of the project, GWM took advantage of simulation topology and MDO (multidisciplinary design) to recognize the most effective material arrangement path that meets performance needs like safety and rigidity. In addition to maintaining the intact ring path structure, GWM aims to improve the torsion resistance, roof crush strength, and rollover protection.

Second, material improvement: greater than “submarine-class” body strength, more than 70% of car materials made of high-strength steel

After fully improving the body structure, the L.E.M.O.N. Platform selects appropriate materials according to the load conditions at different places, and arranges the materials at the most effective location, in order to bring into full play the material efficacy. In a manner of speaking, material improvement is the simplest and most direct solution in the field of light weight.

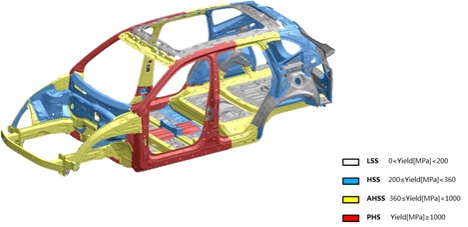

L.E.M.O.N. Platform Body Material Diagram

(White=low-strength steel; blue =high -strength steel; yellow =advanced high-strength steel; red =thermo-forming steel)

Also, L.E.M.O.N. Platform attaches much importance to material improvement: it replaces traditional 1500MPa thermo-forming steel with 2000MPa thermo-forming steel for the first time. As a result, the yield strength rises by 26% and the tensile strength rises by 38%. For example, at the third-generation HAVAL H6’s key parts (like Column A, Column B, and door frame), the baffle bearing pressure reaches 2000MPa, which is greater than the submarine-class body strength (1500MPa) that is advertised by JV car brands. “Blue” denotes high-strength steel, “Yellow” denotes advanced high-strength steel, and “Red” denotes thermo-forming steel, and the three kinds of steel contribute to more than 70% of the car materials, and is the major component of the car body.

The third-generation HAVAL H6

Third, process improvement: break the industry common practices, and introduce the rolling process for steel plate of different thicknesses for the first time.

Besides, L.E.M.O.N. Platform constantly strives for perfection in the process, making possible “Healthy Weight Loss”. It improves the integrality of components, reduces the component weight, and cuts down the overlap edges of components to lessen the weight. By reinforcing the join strength, L.E.M.O.N. Platform makes the path smoother, which provides space for reduction of weight of other components, leading to lighter weight of the whole car.

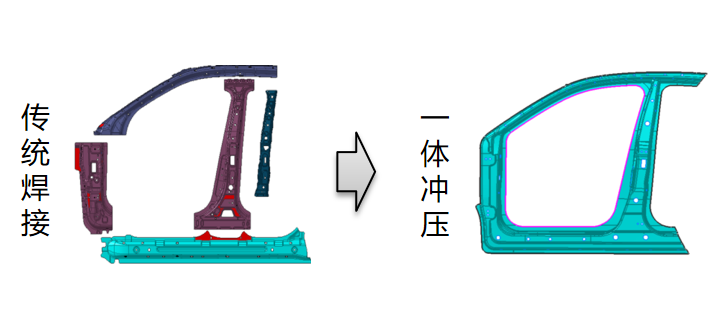

In terms of L.E.M.O.N. Platform car models like the third-generation HAVAL H6 and HAVAL Dagou, traditional spot welding spliced door ring is replaced by integrated hot stamping door ring, which helps remove the centralized collision stress at the joint position along the force transferring path, reduce the body intrusion in the collision, and improve the passenger safety in 25% small overlapping collision conditions. Also, L.E.M.O.N. Platform breaks traditional constant-section steel plate design and introduces the rolling process for steel plate of different thicknesses for the first time, leaving no “Unwanted Fat” for the body.

Traditional spot welding spliced door ring replaced by integrated hot stamping door ring

According to experiments, if a car’s curb weight decreases by 100kg, the fuel consumption per 100 kilometers will decrease by 0.3L-0.6L. In addition, if a car’s weight decreases by 100kg, the carbon dioxide emission will decrease by about 5g per kilometer. After upgrading at the L.E.M.O.N. Platform, GWM’s lightweight level is improved remarkably: the third-generation HAVAL H6’s total weight decreases by 100kg, with fuel economy rising by 14.5% and fuel consumption per 100 kilometer down to 6.6L. Compared to GWM car models of the previous generation, the third-generation HAVAL H6 makes remarkable progress and outshines car models of the same class. If a car’s driving distance is 30,000 kilometers per year, GWM’s car user may save fuel by 180L per year.

On the part of consumers, material improvement will not only contribute to improvement of fuel economy, but also bring them fully optimized driving experience. Overseas survey data show that if a car’s weight decreases by 10%, its accelerating performance will rise by 8%, with braking distance decreasing by 5%, so that the driving will be safer and more efficient. That will fully ensure the driver and passengers’ safety of property and life.

All in all, L.E.M.O.N. Platform, as one of the industry advanced lightweight platforms, will not only bring consumers cars with better fuel economy, but improve the vehicle safety and driving experience, bringing consumers more economical, eco-friendly, comfortable, and safer driving experience. How many mysteries will “GWM L.E.M.O.N.” will bring us? We believe that the upcoming competitive car models will give us more satisfying answers!