The World's First Transverse 9-speed Wet-type Dual Clutch Transmission Rolled Off the Line, GWM Formally Released its New Generation Powertrain

On November 19, the new generation powertrain independently developed by GWM formally rolled off the line at HYCET Yangzhong Industrial Park.

Summary:

GWM new generation powertrain released, covering the fields such as high fuel efficiency, hybrid and pure electric with industrial leading technology;

The world's first transverse 9-speed wet-type dual clutch transmission formally rolled off the line; new generation powertrain, engine, transmission and relevant control software are all independently developed by GWM;

After fully reached the design capacity, the annual output of HYCET Yangzhong Industrial Park will be up to 2.5 million, thus powerfully support the GWM global development.

On November 19, the new generation powertrain independently developed by GWM formally rolled off the line at HYCET Yangzhong Industrial Park. The new generation powertrain, including the GW4N20 engine, the world's first transverse 9-speed wet-type dual clutch transmission - the 9DCT transmission, the 9HDCT transmission, and the three-in-one electric drive assembly, comprehensively covers the fields such as high fuel efficiency, hybrid and pure electric, indicates that GWM takes a great leap forward on the road of independent development; it also provides powerful technical support to develop more new vehicles on the GWM new model platform, and it is of a landmark significance.

HYCET Powers the Future

Over the years GWM always adheres to the R&D philosophy of "precise input, pursue industry leadership". In the "new four modernizations" trend, GWM is working on building a full-ecology and whole-scene blueprint of mobility, in order to provide users with more comfortable and green experience.

The world's first transverse 9-speed wet-type dual clutch transmission leads the industry

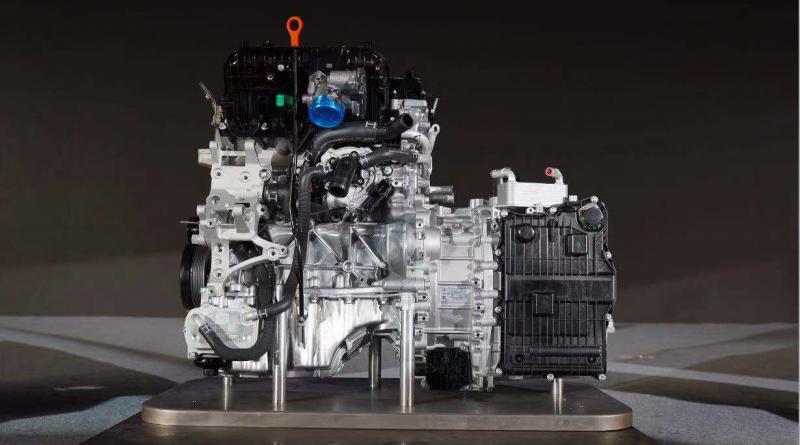

The GW4N20 engine was just honored as one of the 2020 Top10 engines of "China Heart"; and the 9DCT transmission is the world's first transverse 9-speed wet-type dual clutch transmission. The synergic work of both has formed the efficient fuel powertrain with the most valuable of GWM, and further satisfied the user demands on "strong power and low fuel consumption".

GW4N20 engine + 9DCT transmission

Due to the core technologies such as Miller cycle, the GW4N20 engine can reach the heat efficiency up to 38.3%, the maximum power of 180kW, and the maximum torque of 385N•m; and it has perfectly balanced the efficiency and the power. The 9DCT transmission has adopted a large number of cutting-edge technologies, such as built-in integral TCU. As compared to the 7DCT transmission, the overall efficiency is increased by 3.5%, the load torque is increased by 54%, the weight is reduced by approximately 10%, and the load length is about 10% shorter.

In term of the economic efficiency that the users care most about, according to the national standard fuel consumption data, the fuel consumption per hundred kilometers of 9DCT transmission is 7% less than that of the 7DCT. So the perfect match with high fuel efficiency engine can actually reduce the user's cost on vehicle use.

Saving 70% fuel, the 4N20+9HDCT hybrid assembly saves energy and reduces emission more "ultimately"

The 9HDCT transmission is the world's first transverse P2 hybrid 9-speed wet-type dual clutch transmission; according to the national standard fuel consumption data, its fuel consumption per hundred kilometers can be 70% less than that of the 7DCT. The match of P2 module with 9DCT transmission is integrated with multiple control functions and has adopted the advanced winding pattern, to achieve the peak power of 120kW and the peak torque of 330N·m.

GW4N20 engine + 9HDCT transmission

The GW4N20 engine + 9HDCT transmission formed the new generation hybrid powertrain of GWM. Compared to the fuel powertrain, it brings more considerable energy-saving and emission reduction benefits, and provides significant value to both the user and the industry.

Furthermore, the new generation powertrain, engine, transmission and relevant control software are all developed independently by GWM. In subsequent development of vehicle models, they can significantly improve the matching optimization of complete vehicle power, chassis and automatic drive, and pave a way to the higher level of automatic driving.

New generation three-in-one electric drive assembly solved the pain points of existing pure electric users

As one of the enterprises vigorously developing the pure electric drive earliest in China, the launch of the new generation three-in-one electric drive assembly means that GWM has made a new breakthrough in the field of pure electric drive.

Three-in-one electric drive assembly

Three-in-one means that the motor, the controller and the reducer are combined as a whole. Comparing to similar products on market, it features low electromagnetic noise, high product reliability, high stability, and high effective power ratio, reflecting the strong technical R&D and integration strength of GWM.

In the new generation three-in-one electric drive system, the motor powers range from 35kW to 200kW and are applied to different grade of new energy models. It has the High system efficiency, compact size for easier arrangement on complete vehicle, excellent NVH performance, which satisfy the requirement of efficient and green traveling, and bring ultimate driving experience for users.

2.5 million annual output facilitated GWM's continuous leading in technology

GWM's new generation powertrain was successfully rolled off, due to the powerful support by the advanced manufacturing technologies of HYCET Yangzhong Industrial Park.

HYCET Yangzhong Industrial Park is the auto technology industrial park second to none in China, where the transmission assembly shop is equipped with 10 (ABB/FANUC) robots to further improve the assembly efficiency and quality. The armature production line for electric drive system is the first full-automatic production line in China, where multiple key working procedures are 100% automated.

Engine production line of HYCET Yangzhong Industrial Park

After reached the full design capacity, the planned annual output of HYCET Yangzhong Industrial Park will be up to 250 million, bringing over 10 billion annual gross output value. This not only supports GMW's continuous technical research and development, but also facilitates GMW's continuous leading in the global competition of automobile technology research and development.

The release of new generation powertrain means that GWM has made a great leap forward on automobile core technology. The independently developed powertrain arrangement covering high efficient fuel power, hybrid and pure electric will become the key technical strength for GWM's deep involving in global competition, boost GWM's global campaign, and raise up more Chinese brands into continuous innovation, and continue to write new chapters for China Creation.